TITLE:

Particle Size

and Shape Analysis Using Microscope

DATE:

17th November

2014

OBJECTIVE:

1. To

analyze and interpret the size and shape of particles with different samples.

2. To

observe and compare the different size of particles under microscope for each

samples.

INTRODUCTION:

In achieving optimum production of

efficacious medicines, the dimensions of particulate solids is one of the

dominant factor. When drug is synthesized and formulated, the particle size of

drug and other powder is determined and this influences the subsequent physical

performance of the medicine and the pharmacological of the drug. This is

because powder with different particle sizes have different flow and packaging

properties, which alter the volumes of powder during each encapsulation or

tablet compression event. For example, the particles which are having small

dimensions will tend to increase the rate of solution.

In order to obtain equivalent diameters, the particle size of powder

have to be analyzed and interpreted. The bulk properties such as particles size

and shape of the powder are determined by using the size of particles. There

are various method that can be used to determine particle sizes and shapes.

Microscopic analysis is the most widely used method in this case. It can

determine the diameter, shape, and surface area that cannot be determined with

the bare eye.

In this experiment, different sizes

and shapes of sands are used as analogue to powder. Various type of sands (150µ,

355µ, 500µ, 850µ, mixed) and two different powders (MCC and lactose) are given

to be analyze. Sand is a naturally occurring granular material composed of

finely divided rock and mineral particles. Sand is used in this experiment as

it is inert, easy to obtain and economical. It exists in various different

sizes ranging from 0.0625 mm (or 1⁄16 mm) to 2 mm. Fine sand is defined as particles between

0.02 mm and 0.2 mm while course sand as those between 0.2 mm and 2.0 mm.

LISTS OF APPARATUS

Light Microscope

Weighing Boat

Spatula

Glass slide and

cover slip

LISTS OF CHEMICALS

Sands( 150µ,

355µ, 500µ, 850µ, mixed )

Lactose powder

MCC powder

PROCEDURE

1. Sands with

sizes of 150µ, 355µ, 500µ, 850µ, mixed, lactose and MCC are placed in the

different weighing boats using spatula. The weighing boats are labeled

according to the content.

2. The

microscope was set up and ready to be use.

3. 150µ sand is scattered

and made fairly flat on the surface of the glass slide, covered with the cover

slip. The particles were

separated one with another to prevent from redundant particle on one place.

4. The sand was

observed under the microscope using 4x100 magnification and 10x 100

magnification.

5. The particles

were observed microscopically and the shape was determined.

6. The shape and

size of particles had been drawn and analyzed

7. Steps 3 to 6

were repeated by using 355µ, 500µ, 850µ, mixed sands, lactose and MCC powder.

RESULTS

150 mic

Magnification : 4x100

Magnification : 10x100

355 mic

Magnification:

4x100

Magnification:

10x100

500 mic

Magnification:

4x100

Magnification:

10x100

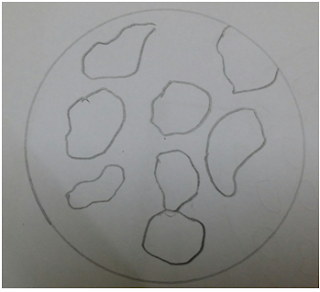

850 mic

Magnification:

4x100

Magnification:

10x100

Various Size

Magnification:

4x100

Magnification:

10x100

MMC

Magnification:

4x100

Magnification:

10x100

Lactose

Magnification:

4x100

Magnification:

10x100

DISCUSSION

Different types of

sands and powders including 150 micron sands, 355 micron sands, 500 micron

sands, 850 micron sands, sands of various sizes, MCC power, and lactose powder

were examined by using light microscope. Light microscope was used in this

experiment because the samples analyzed have particle size range from 0.1

micrometer to 100 nanometers.

The experiment was

carried out to determine the size and shape of the different samples. From the

observation, the shape of the sand particles is asymmetry and irregular whereas

the shape of powders is almost constant and regular for all particles. The

particle shape can be categorized by its sphericity, and characterized into

very angular, angular, sub-angular, sub-rounded, rounded and well-rounded.

It is impractical to

determine the particle size for more than one dimension as the particles are

irregular with different number of faces. The size analysis is carried out on

two-dimensional image of particles which are generally assumed to be randomly

oriented in 3-dimensional. Therefore, the solid particle is approximate to a

sphere and the particle size is analyzed by determining its equivalent diameter.

There are different types of equivalent diameters which include projected

perimeter diameter, projected area diameter, Feret’s and Martin’s diameter. The

projected perimeter diameter is based on a circle having the same perimeter as

the particle. The projected area diameter is based on a circle of equivalent

area to that of the projected image of a solid particle. Feret’s diameter is

the mean distance between two parallel tangents to the projected particle

perimeter while Martin’s diameter is the mean chord length of the projected

particle perimeter.

There are precautions

must be taken in this experiment. All the observations should be done under the

same magnification so that the comparison between the different samples in

terms of size and shape can be done. During the preparation of the slide, the

sand particles is spread and dispersed evenly on the slide until it appeared as

a thin layer to avoid agglomeration.

QUESTIONS

1) Explain in brief the various

statistical methods that you can use to measure the diameter of a particle.

The various statistical

methods that use to measure the diameter of particles are projected perimeter

diameter, projected area diameter, Feret’s diameter and Martin’s diameter. The

projected perimeter diameter is based on a circle having the same perimeter as

the particle. The projected area diameter is based on a circle of equivalent

area to that of the projected image of a solid particle. Both of these methods are independent

upon particle orientation and

only take into account of 2 dimensions of the particle. Feret’s diameter is the

mean distance between two parallel tangents to the projected particle perimeter

while Martin’s diameter is the mean chord length of the projected particle

perimeter. Both of these methods consider the orientation of the particle. Both

Martin’s diameter and Feret’s diameter are used in particle size analysis by electron

microscopy

2) State the best statistical method for

each of the samples that you have analyzed.

The best statistical

method is Feret’s and Martin’s diameter.

CONCLUSION

The shape of the both MCC and lactose

powder is regular whereas the shape of various types of sands is irregular. The

particle size of the samples in ascending order is lactose powder, MCC powders,

150 micron sands, 355 micron sands, 500 micron sands, 850 micron sand. In sands

of various sizes, some of the sands having the largest size among all types of

sands.

REFERENCE

1) Pharmaceutics, The science of dosage form design

(2nd Edition) Michael E.Alton Edinburgh London New York Philadophia St Louis

Sydney Toronto 2002.

2)

Physicochemical Principals of Pharmacy (2nd Edition) AT Florence and D.Attwood,

The Macmillan Press Ltd.